Photographs taken 2010

Geevor Mine is the most important monument to the Cornish Tin Mining industry that exists today in Cornwall. It is a part of the extensive Cornish Mining World Heritage Site, and was a working tin mine right up to 1990, when it finally, and very sadly, closed. Geevor is in the same St Just mining area of Cornwall as the Levant Mine and the Botallack Mine. The main working shaft is Victory Shaft, that took over prominence from the earlier Wethered Shaft, whose head-gear can still be seen as you enter the Geevor Mine site. Attached to the Victory Shaft and built just down-slope, is the now preserved Tin Mill that processed the tin ore - Cassiterite - that was brought up the shaft. These were only the latest mine workings constructed here - before the Geevor Tin Mines Ltd company took over mining operations in 1911. Before this the site was mined by the North Levant Mine between 1851 and 1891, and earlier still, a number of mines were operating on the site, including Wheal Geevor and Wheal Mexico. The workings of the latter were only recently re-discovered, and have now been opened up for underground tours. Much earlier than this, there have been traces of mining activity that have been found on the site, dating back as much as 4,000 years. Tin, after-all, was a major component of the Bronze Age!

Geevor Mine, with Victory Shaft and the Tin Mill beyond

Victory Shaft was sunk in 1919, or at least started then, and the original wooden head-gear was added in 1924. The newer metal head-gear was constructed over the old wooden head-gear in 1954. Victory Shaft was designed and built as a multi-use shaft, containing both a cage for miners, and a skipway - or "skip-road" for bringing the mined ore to the surface - or "to grass". The standard mine shaft in Cornwall during the twentieth century measured 15ft x 6ft, and the compartments within the shaft for ore lifting and miners' cages were separated by heavy timber-work. There also needs to be space allocated at the sides within the shaft, for mine services such as ventilation and rising mains for pumping out water. In addition, space is required for ladder access - used during construction and for emergency and maintenance access - and, in earlier times particularly during the nineteenth century, space for pump rods driven by the Cornish Beam Engines installed in the now disused iconic mine engine houses, that can still be seen all around the old mining areas of Cornwall.

The head-gear over the main working shaft - Victory Shaft

Geevor Mine has been left almost as it was when it closed in 1990. The Miners' Dry - where the miners changed and prepared to go underground, and more importantly changed after their shift, is as they left it. It is a memorial to the mine and the miners that worked here. Where they grafted, and where they lived their working lives. The whole mine site shows a working tin mine as it was at the end of the twentieth century, with all its surface support buildings, its ore processing works, and the story of those who worked there, both above and below ground. It is a visit you will remember.

Looking at Victory Shaft from the opposite side showing the skip

access tracks

Looking up the Victory Shaft head-gear and maintenance ladder, with

one of the ore skip shovels

Victory Shaft cage and skip access

One of the photos on display at Geevor of miners entering the cage

on Victory Shaft

Looking up the head-gear above the miners' cage

The shaft below the cage

The emergency ladderway access down Victory Shaft to the left of the

cages

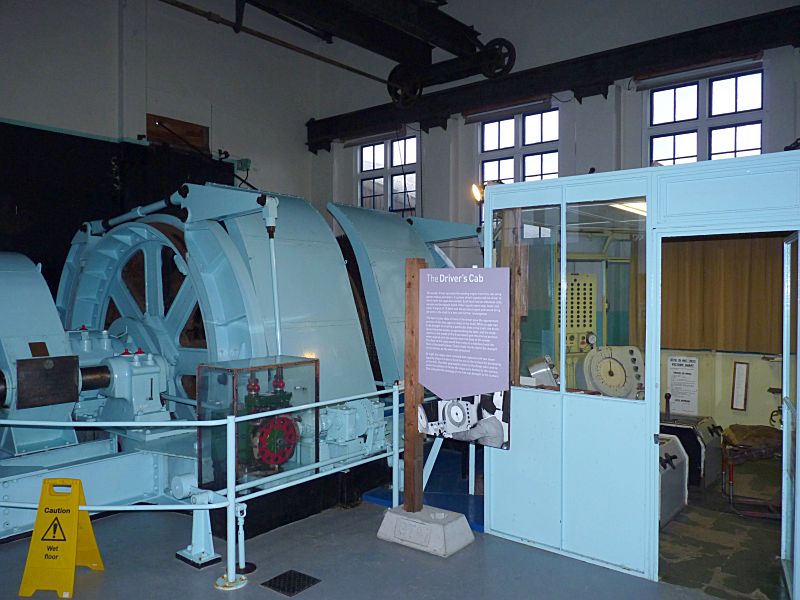

The Winding Room and Cab for Victory Shaft

As with all mining, tin mining over the past centuries has been a dangerous undertaking. The modern Geevor Mine was however a comparably much safer place to work. Safety was always paramount, and two mine rescue teams were maintained. They were equipped with oxygen re-breathing equipment, much the same as re-breathing diving apparatus.

Geevor Mine Rescue Team - Equipment Room

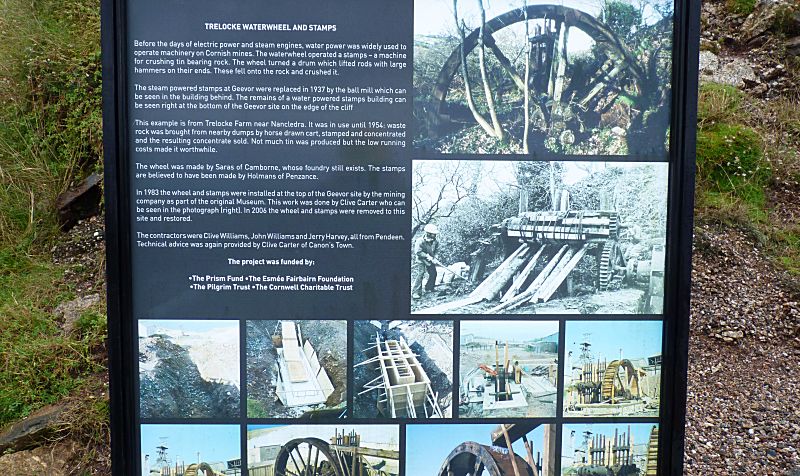

Once the ore was brought to the surface of a mine, it needed to be broken into smaller manageable chunks. This was in earlier days the job of the steam-driven, or waterwheel-driven "stamps". At Geevor, an early example of a set of waterwheel-driven stamps were brought to the first museum here in 1983, having been recovered from Trelocke Farm near Nancledra. These stamps were still in use until 1954 crushing waste material from local mine surface dumps. At Geevor, the original steam-driven stamps were replaced in 1937 by the rotating ball-mill installed in the new Tin Mill.

The restored Trelocke Waterwheel and Stamps

The story of the Trelocke waterwheel - originally worked at Trelocke

Farm near Nancledra until 1954

A lot of ironwork and equipment was gathered together for sale as scrap when Geevor finally closed, and the remains of this serve as a reminder of the industry and endeavour that once breathed life into this mine, and has now passed on.

Old mining equipment piled up at Geevor

The World Below

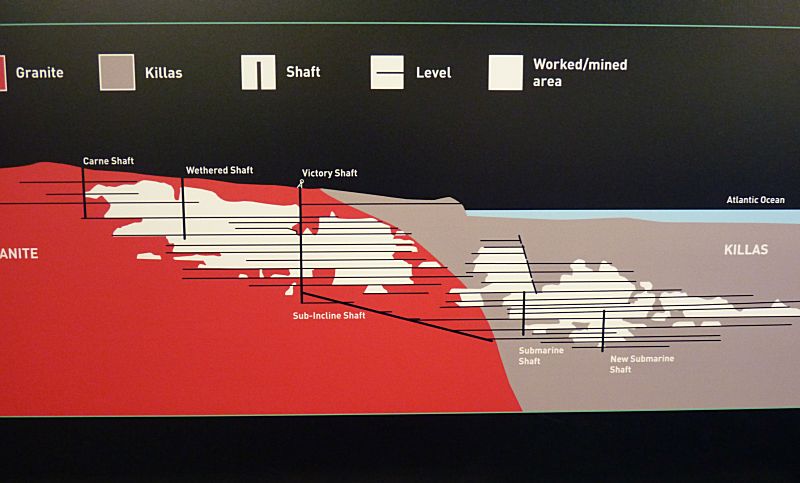

The shafts and adits that can be seen on the surface, as they enter the underworld below, belie the true extent of these mines as they are below ground. Excavations underground follow the ore lodes that yield the tin and copper, and in many cases, other valuable minerals that can yield a profit. These lodes generally occur as vertical sheets, sometimes feet wide, and up to thousands of feet deep, where the minerals and ores have coalesced in faults in the igneous (volcanic) granite bedrock as it formed during geological ages past. Where these lodes have been evident on the surface, the first mines were worked, often as open-cast or "lode-back" workings, or as shallow excavations into a hillside or cliff - the first adits in crude form. As these surface deposits were exhausted, there was a need to go deeper to reach the valuable ore. Shafts were sunk, and levels driven out along the lodes, and minerals extracted by forming "stopes" above or below these levels where the ore was broken out by drilling and blasting, to be hauled out along other levels in man-hauled skips, and back to the shafts where they were winched up to the surface in buckets or "kibbles".

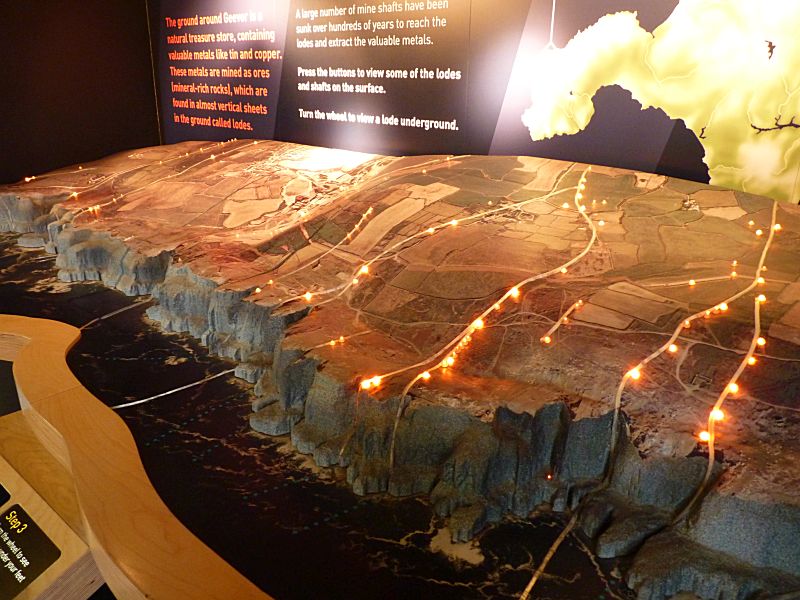

But the mining engineers following these lodes needed to know where they were! The model at Geevor shown below, illustrates the main ore lodes at the surface, and where the mine shafts were sunk along or next to these lodes.

The shafts and lodes along the coast in model form - the lines

represent the thin vertical sheets, or lodes of tin

(The Geevor

Mine is in the valley just under the white light)

As the mines were extended, the number of underground levels, access tunnels and shafts grew and spread along the lodes, sometimes even linking different lodes and mines together. With no way of looking around to see in which direction they were headed, the view being a little, shall we say, restricted, mine surveyors and engineers had to rely on compass and theodolites to physically measure direction, depth, distance, and ultimately position. By this method mine plans could be plotted, shafts sunk, and levels driven forward. Mistakes could be fatal. In 1893 at Wheal Owles in the St Just district, an error in surveying, due to the failure to take into account the effect of compass magnetic variation over a period of several years, resulted in the adjacent flooded mine workings of Wheal Drea being breached. Twenty miners sadly lost their lives. The complexity of underground workings can be seen in this attempt to three-dimensionally plot the Geevor, Levant and surrounding mine workings in the model below...

Not an easy thing to depict - the maze of mine shafts and levels

that have been excavated underground

(The "ladder" rods are only

there to support the shaft and level mine tunnels)

Cross-section through the vertical tin lode mined at Geevor

One major part of the Geevor Tin Mine site is the Hard Rock Museum. This also has a small cinema showing a film of Geevor as it was as a working mine. The main part of the museum is an extensive display of minerals that are found underground - not only the tin and copper ores that attract the mining companies, but also the great range of other minerals that naturally occur in the rich lodes that formed in these igneous granite areas of Cornwall, during its geological past.

Amethyst Nodule in the Hard Rock Museum at Geevor

See also Geevor Mine - Underground in Wheal Mexico and Geevor Mine - The Preserved Tin Mill

Visit the Geevor Mine website

There are also some excellent black and white images at Cornish Mine Images

Connect with us, Like us and Follow us on Facebook!

PhotoFile Cornwall supports CoaST and Sustainable Tourism